Underground Construction: What You Need to Know

When working with underground construction, the practice of building tunnels, shafts, and other structures beneath the earth’s surface. Also known as subterranean engineering, it requires careful planning, precise execution, and constant safety monitoring.

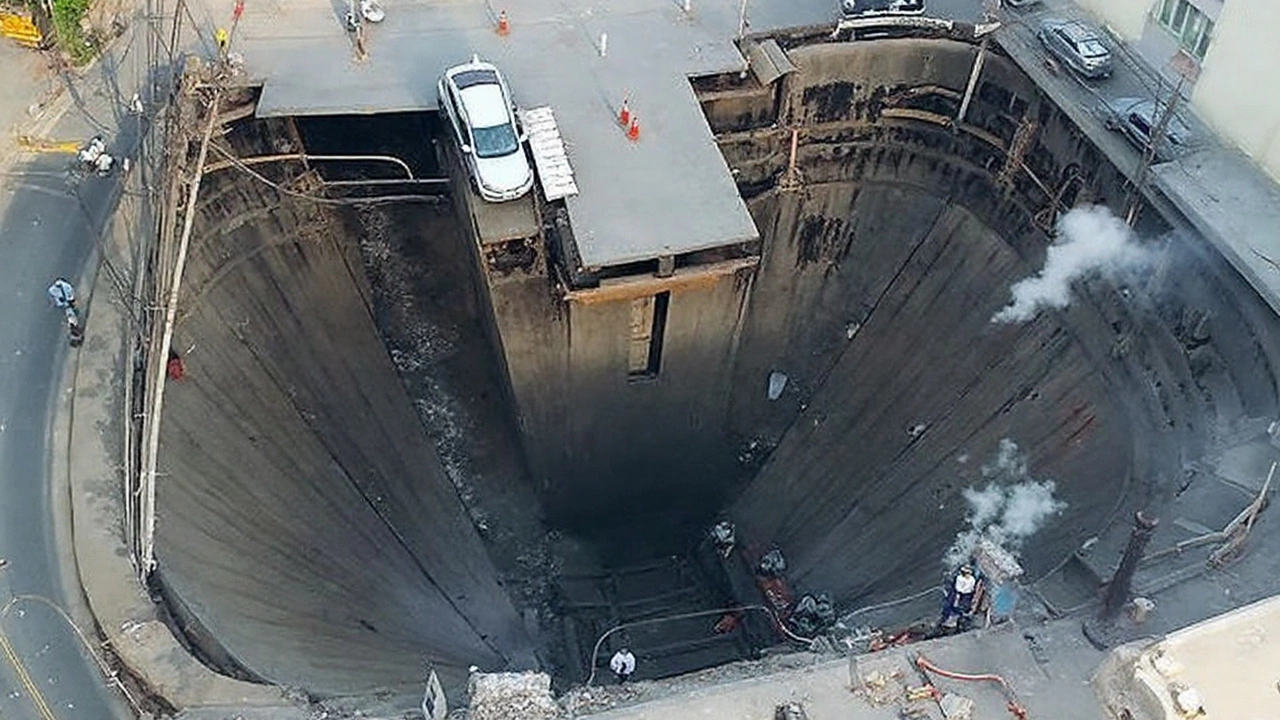

One of the core activities inside this field is tunneling, the process of excavating a passageway through rock, soil, or other ground conditions. Tunneling can be done with traditional drill‑and‑blast methods or with modern Tunnel Boring Machines (TBMs) that push through the earth while installing lining segments. Underground construction also relies heavily on ground investigation, the systematic study of soil and rock to predict how the ground will behave during excavation. Without accurate ground data, you risk collapse, water ingress, or costly delays.

Another essential piece of the puzzle is structural support, the system of liners, rock bolts, shotcrete, and steel ribs used to keep the excavated space stable. Proper support design follows the findings from ground investigation and matches the tunneling method chosen. When support and excavation work hand‑in‑hand, the whole project stays on schedule and within budget. Adding a layer of efficiency, trenchless technology, methods like pipe jacking, microtunneling, and horizontal directional drilling that install utilities without open‑cut trenches, reduces surface disruption and speeds up construction in urban areas.

How These Elements Fit Together

Underground construction encompasses tunneling, ground investigation, structural support, and trenchless technology. It requires a seamless flow of data from soil testing to machine operation, and it influences urban planning by allowing new transit lines, water conduits, and underground facilities to coexist with existing infrastructure. For example, a city planning a subway extension will start with intensive ground investigation, decide on the right tunneling method, select appropriate support systems, and then use trenchless techniques to install power and communication lines without tearing up streets.

Safety is not an afterthought—it's woven into every step. Monitoring equipment measures pressure, movement, and gas levels in real time, while workers follow strict protocols based on the support design. When a change in ground conditions is detected, the support plan can be adjusted on the fly, preventing accidents before they happen.

Whether you’re a seasoned engineer, a contractor eyeing new projects, or a curious homeowner wondering how that new underground parking garage was built, the collection below shows how each piece of the puzzle comes together in real‑world projects. You'll see examples of tunneling breakthroughs, innovative trenchless installations, and the latest safety standards that keep everyone on the ground—and below it—secure. Dive in to see the breadth of techniques and learn practical tips you can apply to your next underground venture.